Playing with Servos

|

|

Well, it came time to connect up some servos for steering, and I figured

I better characterize my servos, so I'd have an idea how they react.

|

|

|

|

Holding Jig

I whipped up a jig using some scraps of wood and plastic that I had. I used

one of the servo horns that came with the servo, and my highly sophisticated

coupler consists of a scrap of 1" round aluminum that was drilled to accept

the shaft of the encoder, with a setscrew to hold things in place.

The encoder is a surplus Oak Grigsby one from somewhere. It has 128 pulses

per revolution, or 512 edges when you start to do quadrature on it.

Bigger...

|

|

|

|

|

|

|

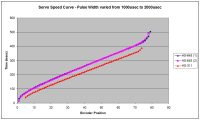

Sweep

The first test I did was to position the servo at the position given

by a 1 millsecond pulse, and then moved it to the position with a 2

millisecond pulse. Recording only the B channel, I recored the time

that each change in encoder position occured and plotted them. I tested 2

Hitec HS-645MG servos and one HS-311 servo.

Bigger...

|

|

|

|

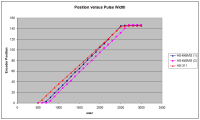

Position

In this test, I set the pulse width to 500 usec, and incremented it by

100 usec, recording the encoder position for each pulse width. It's

interesting to note that the two HS-645's didn't quite move the same amount

and the two extreme positions were at different places. HS-645-1 started to

move before HS-645-2 but stopped sooner.

Bigger...

|

|

Home

- Line Maze 2006

|