|

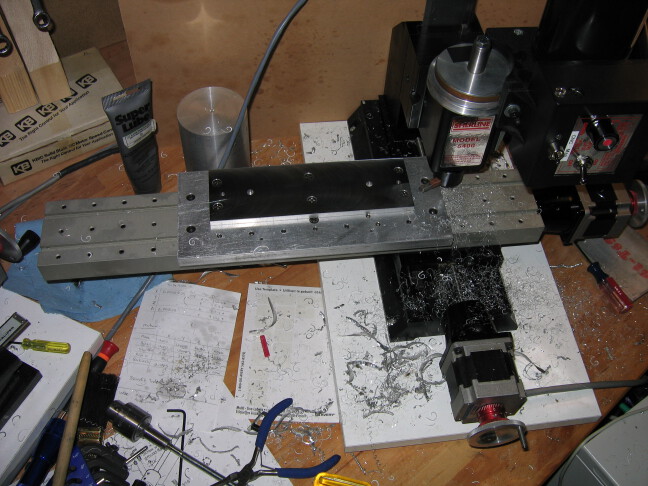

As luck would have it, the very first project that I had to do after

installing the long table was to flycut a 7.5" piece of aluminum. Using

the fly cutter and clearing the material on each side requries approx

2.5" of extra travel. This means I would have needed 10" of travel, which

isn't possible with the Sherline table, but fits well within the A2ZCNC table

quite nicely.

If you look closely, you'll notice that I filled all of the tapped holes

with set screws (to keep the swarf out). I suggested to Tim that he provide

set screws with the tapped version of the table, and Tim indicated to me

that future orders will include the set screws.

Bigger...

|