Example of Jig Usage

| We were talking about jigs on the SherlineCNC list, and so I decided to publish a few photos of a part I'm making for one of my robots. |

|

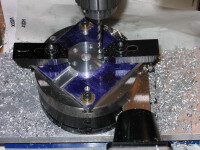

Drilling the holesHere's the jig in place, drilling some holes. Notice that I'm using the heads of the socket head cap screws to support under the clamps. Bigger... |

|

Swarf removedHere's the part mounted in the jig, with the swarf removed. Bigger... |

|

JigAnd here's a photo of the jig itself. The recess is about 0.060" deep, and the diameter of the circle is 1.4". The "slot" coming out at an angle was machined at the same time and to the same depth as the recess. This allows a spot for my feeler gauge when I want to refernce to the surface. There's still some more machining to do, so the the 0.060" deep side walls are deep enough that I can use an indicator to get things lined back up again when the time comes. I also machined a 1/16" groove all around the base of the outside wall so that the part wouldn't get caught in a not quite square corner (between the flat bottom and side walls). Bigger... |

|

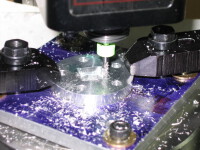

Machining Square HoleI'm using a 1/16" endmill to machine the square hole. This hole is square since it needs to transfer power to the hub and onto the wheel. Bigger... |

|

Ready to TaperThe hub is now ready to have the taper machined. Bigger... |

|

Finished TaperThe taper is all done. Bigger... |

|

Assorted PiecesHere's some of the pieces and how they fit together. The black portion at the top is the disc brake mechanism (testing for fit). Bigger... |

Home - Machinist - CNC